AI-Driven Design: How Generative Intelligence Is Reimagining the Shape of Things

The Creative Convergence of Artificial Intelligence and Additive Manufacturing

🧭 Introduction: When Machines Learn to Create

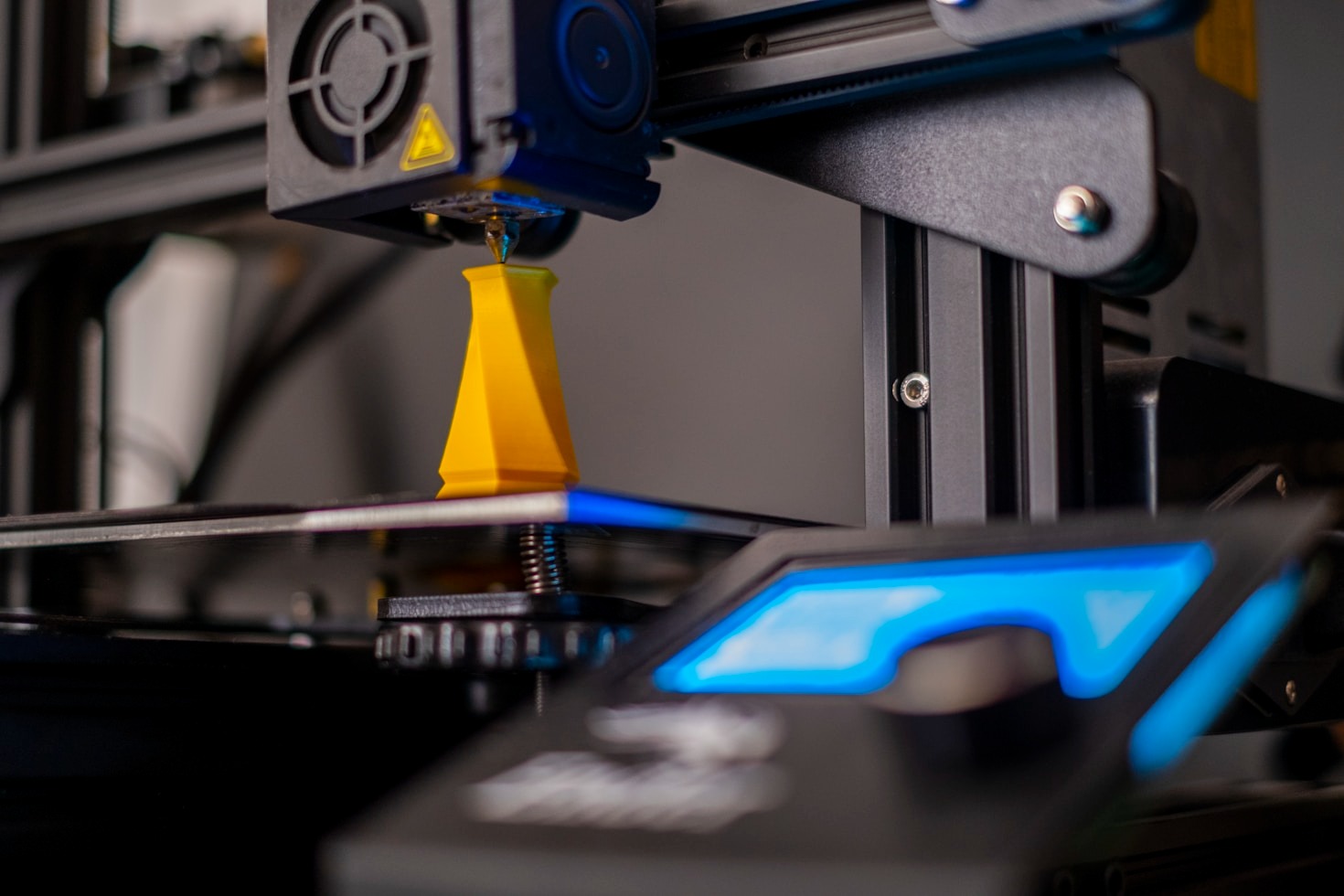

For centuries, design has been a human domain — guided by intuition, aesthetics, and experience. But today, artificial intelligence (AI) is emerging as both collaborator and catalyst in the creative process.

When combined with 3D printing, AI becomes something entirely new: not just a tool, but a co-creator capable of dreaming up structures no human could sketch and producing them directly into physical form.

At 3D Printing Ventures, we view this as a cornerstone of the next industrial paradigm — where AI-generated designs merge with additive manufacturing to build smarter, lighter, and more sustainable products across every industry.

“In the 20th century, we taught machines how to build.

In the 21st, we’re teaching them how to think.”

— Rich Benvin, 3D Printing Ventures

⚙️ The Shift from Design to Discovery

Traditional design is deterministic: engineers define a form and test its limits.

AI-driven design is evolutionary: algorithms explore thousands of permutations, optimizing geometry, strength, and material use simultaneously.

This new paradigm — called generative design — uses algorithms inspired by nature, physics, and evolution to “discover” shapes rather than draw them.

Engineers simply set goals and constraints (e.g., weight, stress tolerance, material type), and the AI system generates optimal configurations — often alien-looking but performance-perfect.

Key Features of AI-Driven Design:

-

Multi-Objective Optimization: Balances strength, mass, cost, and thermal performance.

-

Organic Geometry: Mimics biological systems (bone, coral, honeycomb) for maximal efficiency.

-

Iterative Learning: Improves with each print, using real-world data to refine models.

-

Mass Customization: Designs unique, user-specific solutions at no extra cost.

With 3D printing’s ability to fabricate these complex shapes directly, form is finally free from the constraints of traditional tooling.

🧠 How It Works: The Generative Feedback Loop

AI doesn’t just design — it learns from every print.

When integrated with additive manufacturing, an intelligent feedback loop emerges:

-

Define Constraints → Engineers specify performance targets and boundaries.

-

Generate Designs → AI produces hundreds or thousands of geometries optimized via simulation.

-

Print Prototypes → Additive manufacturing produces the most promising candidates.

-

Sense & Analyze → Embedded sensors capture stress, vibration, and deformation data.

-

Learn & Refine → AI retrains models based on real-world performance.

This continuous learning process transforms manufacturing into a living system — one that improves itself autonomously.

“We’re moving from CAD to cognition — where every design teaches the next one.”

— 3D Printing Ventures Research Team

🚀 Applications Across Industries

Aerospace:

Airbus and GE are already printing AI-optimized brackets and fuel nozzles that are 50–80% lighter than machined parts while maintaining or improving performance.

Healthcare:

AI-generated orthopedic implants adapt precisely to each patient’s anatomy, improving healing rates and comfort while minimizing invasive procedures.

Automotive:

Electric vehicle startups are using AI + additive manufacturing to print integrated chassis components, reducing part count and enhancing crash energy absorption.

Consumer Products:

Fashion and footwear brands deploy generative design to create customizable, ergonomic, and recyclable products that blur the line between art and engineering.

🧩 AI Meets Physics: Digital Twins and Predictive Simulation

Generative design alone is powerful — but when paired with digital twins, it becomes transformative.

A digital twin is a high-fidelity virtual replica of a product or process.

AI algorithms use these twins to simulate real-world stress, fatigue, or environmental conditions before any physical prototype is built.

Combined with 3D printing, this means:

-

Zero-waste iteration

-

Faster certification cycles

-

Embedded simulation data in each part’s “digital DNA”

-

Continuous optimization across the product lifecycle

Ultimately, products evolve like living organisms — continuously adapting to their environment through data feedback.

🤖 The Human + Machine Design Partnership

Far from replacing designers, AI augments them.

Engineers set creative direction, ethical boundaries, and functional goals — the AI explores millions of possibilities within those parameters.

This partnership amplifies human creativity:

-

AI generates ideas humans wouldn’t consider.

-

Humans provide intuition, empathy, and purpose.

-

Together, they push design into previously unreachable dimensions.

At 3D Printing Ventures, we believe this collaboration represents the symbiosis of imagination and intelligence — a fusion that defines Industry 5.0.

🔗 Integration with Blockchain and Provenance

As AI begins to generate valuable IP at machine speed, blockchain ensures authorship, licensing, and traceability.

-

Every AI-generated model can be tokenized as a digital asset (NFT or cryptographic hash).

-

Ownership and royalty rights can be embedded directly into the design’s metadata.

-

Print jobs can be governed by smart contracts, ensuring fair use and compensation.

-

Audit trails track every modification, training dataset, and final iteration.

This is where 3D Printing Ventures’ Tokenized Factory framework ties in — protecting digital creativity while enabling open innovation.

🧠 AI + Robotics + 3D Printing: The Self-Designing, Self-Building Factory

Additive manufacturing and AI don’t stop at design; they extend into production.

AI-driven robots are learning to:

-

Auto-calibrate print beds

-

Adjust parameters in real time

-

Perform quality inspection and maintenance

-

Collaborate across multiple printers autonomously

Together, AI and robotics form the foundation of self-building factories — agile production cells that can print, test, and repair without human oversight.

As 3D Printing Ventures invests in startups integrating these capabilities, the line between “design” and “manufacturing” disappears.

The product, the printer, and the AI become one continuous intelligence loop.

⚛️ Quantum Computing: Accelerating Generative Intelligence

Quantum computing will amplify this synergy exponentially.

Quantum algorithms excel at solving multi-variable optimization problems — the heart of generative design.

Future quantum-AI systems could:

-

Explore billions of design permutations simultaneously

-

Simulate atomic-level material properties in seconds

-

Discover new alloys or composites optimized for additive manufacturing

-

Enable real-time design optimization during printing

In short, quantum design + additive production = instant innovation.

It’s not just faster design — it’s post-human creativity at industrial scale.

🌱 Designing for Sustainability

AI-driven generative design doesn’t just create beauty — it creates efficiency.

By minimizing material use and maximizing strength, additive manufacturing with AI drastically reduces waste.

Key sustainability gains:

-

60–90% reduction in raw material usage

-

Lighter parts = lower fuel consumption and emissions

-

Locally printed components = reduced logistics footprint

-

AI lifecycle analysis = measurable circularity metrics

3D Printing Ventures promotes investments that measure eco-efficiency as a KPI, ensuring that technological progress aligns with planetary health.

💡 The Investment Angle: Betting on Intelligent Design

As AI reshapes additive manufacturing, investors are flocking to convergence startups building the design tools and platforms of the future.

Opportunities include:

-

Generative design software startups (AI + simulation)

-

Additive manufacturing AI platforms (real-time defect detection and optimization)

-

AI-driven materials discovery firms

-

Blockchain design marketplaces (tokenized design IP)

These companies don’t just sell software — they sell intelligence-as-infrastructure for the coming industrial renaissance.

🧭 The 3D Printing Ventures View

At 3D Printing Ventures, we see AI as the creative intelligence layer in the broader additive ecosystem.

It bridges imagination and execution — transforming the way ideas move from screen to reality.

Our mission is to fund and accelerate startups that merge:

-

AI design intelligence

-

3D printing and materials innovation

-

Blockchain provenance systems

-

Robotic manufacturing automation

-

Quantum simulation frameworks

Together, these technologies form a closed loop of creation — intelligent, ethical, and exponentially scalable.

🧩 Conclusion: The Shape of Tomorrow

We are entering an age when machines design better than we can imagine — but always under human guidance.

AI and 3D printing together form the creative engine of Industry 5.0, where innovation becomes infinite, ownership transparent, and production sustainable.

“AI doesn’t replace creativity — it multiplies it.

And 3D printing turns that creativity into reality.”

— Rich Benvin, 3D Printing Ventures

The future of manufacturing isn’t just smart — it’s imaginative, adaptive, and alive.

And it’s already printing itself into existence.

Leave a Reply