Blockchain’s Impact on Decentralized Manufacturing

How Distributed Ledgers, Smart Contracts, and Tokenized Assets Are Redefining Global Production Networks

🔗 Introduction: From Supply Chains to Value Webs

For centuries, manufacturing has relied on centralized systems — factories, distributors, and corporate hierarchies controlling production.

But the future is decentralized.

Blockchain technology is enabling a new industrial paradigm: trustless, peer-to-peer manufacturing.

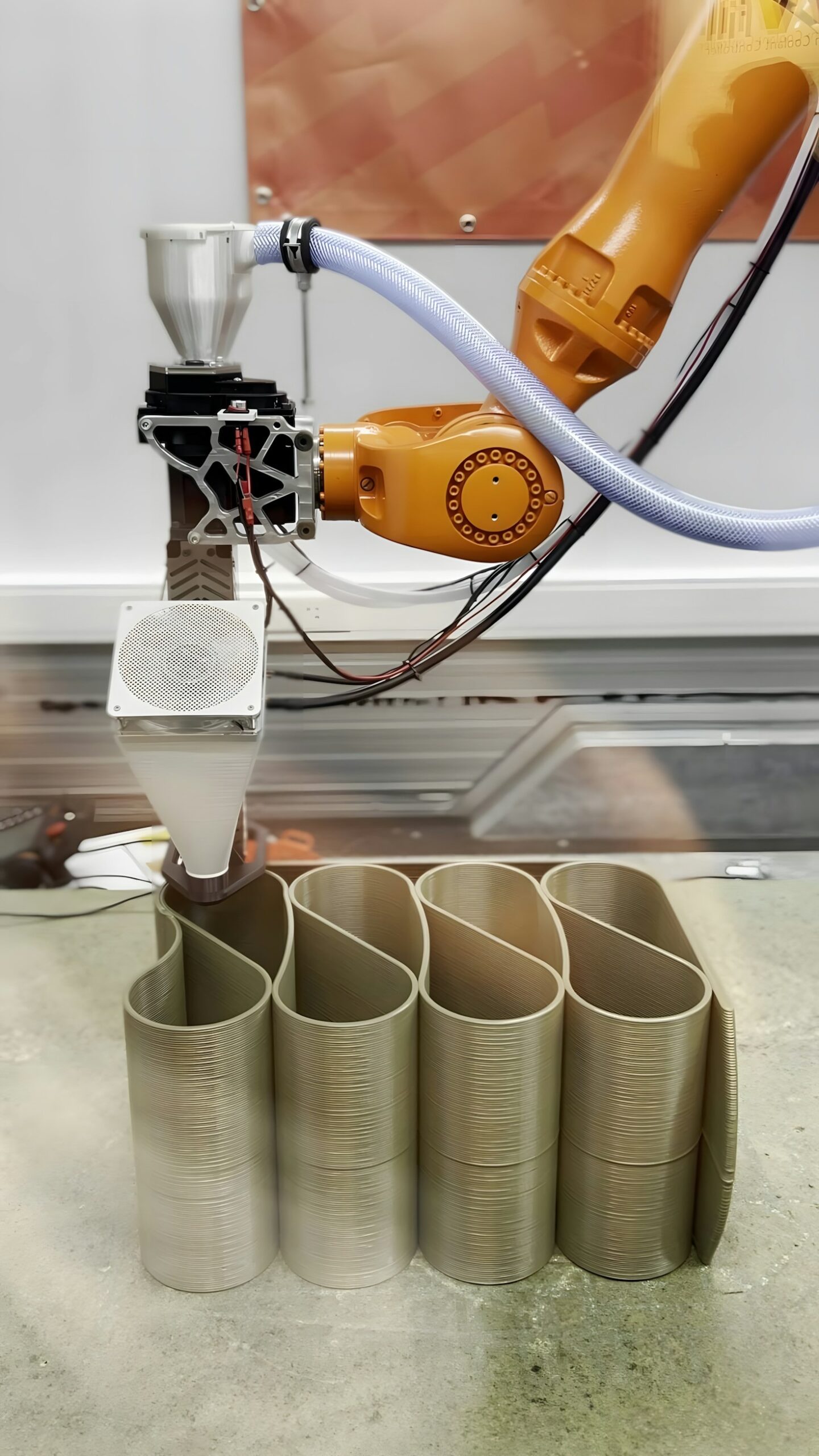

Instead of top-down supply chains, we’re entering an era of interconnected value webs — networks of 3D printers, designers, suppliers, and autonomous robots collaborating across borders through smart contracts, cryptographic trust, and tokenized incentives.

At 3D Printing Ventures, and through the 3D Printing Coin ($3DP) at 3DPrintingCoin.com, we are building this decentralized manufacturing ecosystem — where blockchain isn’t just a financial tool, but the operating system of a new industrial economy.

“Blockchain turns supply chains into ecosystems — where every participant is both a contributor and a stakeholder.”

— Rich Benvin, Founder, 3D Printing Ventures & 3D Printing Coin

🧱 The Core Shift: From Centralized Production to Decentralized Coordination

Traditional manufacturing relies on centralized authority for coordination — corporate logistics, vendor management, and legal contracts.

This model is slow, opaque, and inefficient.

Blockchain replaces central authority with code, creating a distributed trust layer that:

-

Verifies authenticity and quality

-

Automates transactions and royalties

-

Enables open collaboration between independent nodes

-

Records every step of design and production in an immutable ledger

In decentralized manufacturing, the factory is no longer a place — it’s a network.

⚙️ The Building Blocks of Blockchain Manufacturing

1. Smart Contracts: Automation Without Intermediaries

Smart contracts are self-executing agreements stored on the blockchain.

They define conditions for collaboration — such as production quotas, royalties, or delivery terms — and execute automatically once those conditions are met.

Example:

A 3D printer in Germany receives a verified design file tokenized as an NFT.

Once the print is complete and quality data matches specifications, the smart contract releases $3DP tokens to both the designer and printer.

No middlemen. No delays. No trust required — only verification.

2. Digital Twin Tokenization

Every manufactured item can be mirrored as a digital twin on the blockchain.

These tokens contain:

-

Source design data

-

Print parameters

-

Material origin

-

Performance history

This digital fingerprint makes every part traceable, auditable, and certifiable, creating full transparency for aerospace, healthcare, or automotive applications.

Blockchain turns physical parts into verifiable digital assets — each with its own lifecycle, royalties, and provenance.

3. Decentralized Manufacturing Networks (DMNs)

DMNs are blockchain-coordinated ecosystems of connected machines and creators.

Instead of central scheduling software, smart contracts handle:

-

Job allocation

-

Bidding and pricing

-

Verification

-

Payment distribution

Imagine thousands of independent 3D printers operating like a decentralized Uber for manufacturing — on-demand, verified, and paid instantly in $3DP tokens.

4. Data Provenance and IP Protection

One of the biggest challenges in additive manufacturing is protecting intellectual property while sharing digital designs.

Blockchain solves this by combining cryptographic design hashes and NFT licensing:

-

Each design is tokenized and registered on-chain.

-

Access is granted through verifiable smart licenses.

-

Unauthorized prints are automatically blocked or penalized.

Designers finally retain control of their work — even as it’s shared globally.

“In a decentralized manufacturing world, blockchain is the lawyer, the accountant, and the notary — all encoded in software.”

— 3D Printing Ventures Legal Framework Team

💠 The Role of 3D Printing Coin ($3DP): The Token of Trust

The 3D Printing Coin ($3DP) powers every transaction, verification, and reward in this decentralized ecosystem.

$3DP enables:

| Function | Description |

|---|---|

| Payments | Instant, borderless payments for verified print jobs, royalties, and materials. |

| Royalties | Automatic distribution of revenue to designers, engineers, and machine owners. |

| Governance | Token-based voting on partnerships, sustainability initiatives, and network rules. |

| Incentives | Rewarding contributors who share designs, certify prints, or maintain uptime. |

In short, $3DP transforms blockchain from a record-keeping tool into a living economy — the foundation of global decentralized production.

🌐 Global Use Cases: Blockchain in Action

1. Aerospace & Defense

Blockchain verifies every component’s origin, ensuring compliance with safety standards and export controls.

A single tamper-proof ledger tracks design changes, test data, and certifications.

2. Medical Manufacturing

Hospitals and labs use blockchain to share and print medical implants with on-chain verification of sterility, biocompatibility, and physician authorization.

3. Automotive Supply Chains

OEMs track 3D-printed tools, fixtures, and replacement parts using NFTs — creating a transparent, zero-fraud parts database.

4. Energy & Sustainability

Decentralized factories powered by renewable energy can tokenize carbon credits, allowing $3DP tokens to represent both economic and ecological value.

🔐 Blockchain Security: Protecting the Factory of the Future

Security in decentralized manufacturing extends beyond IP — it includes data integrity, privacy, and trust between autonomous machines.

Blockchain provides:

-

Immutable Audit Trails — Every print job and material change is logged permanently.

-

Machine Identity (MID) — Each printer, robot, and sensor has a cryptographic signature.

-

Zero-Knowledge Proofs (ZKPs) — Validate authenticity without exposing sensitive design data.

-

Post-Quantum Readiness — Future integration with quantum-resistant ledgers ensures long-term security.

These features allow machine-to-machine trust — the cornerstone of the coming autonomous factory economy.

⚙️ How Blockchain Transforms the Manufacturing Workflow

| Step | Traditional Model | Blockchain Model |

|---|---|---|

| Design | Centralized CAD systems | Tokenized NFT design registry |

| Licensing | Legal contracts & NDAs | Smart contracts with automatic royalties |

| Production | Factory scheduling | On-chain job bidding and verification |

| Quality Control | Manual audits | Real-time blockchain validation |

| Payment | Bank transfers | Instant crypto settlement ($3DP) |

| Provenance | Paper trails | Immutable digital twin |

This shift replaces bureaucracy with automation — turning manufacturing into a trustless digital ecosystem.

🧭 The 3D Printing Ventures Vision: The Tokenized Factory Network

3D Printing Ventures is developing the infrastructure for The Tokenized Factory — a globally distributed, blockchain-coordinated system where:

-

Designers earn royalties for every licensed print.

-

Manufacturers operate as verified nodes rewarded in $3DP.

-

Investors fund projects through decentralized venture pools.

-

Consumers gain transparency into every product’s origin and sustainability.

The Tokenized Factory merges additive manufacturing, AI, robotics, and blockchain into one synchronized loop of creation and reward.

“We’re not decentralizing factories — we’re decentralizing creativity itself.”

— Rich Benvin, 3D Printing Ventures

🧠 Blockchain + AI + Quantum: The Intelligent Industrial Stack

In future iterations, blockchain will integrate directly with AI optimization and quantum simulation:

-

AI models will analyze blockchain data to predict demand and automate sourcing.

-

Quantum algorithms will optimize production scheduling and energy efficiency.

-

The $3DP blockchain will serve as the truth layer, recording every digital-physical event.

Together, these systems create a self-learning, self-verifying, and self-financing industrial network.

💰 Investment and Opportunity

The fusion of blockchain and manufacturing represents a multi-trillion-dollar opportunity across:

-

Supply chain transparency

-

IP tokenization

-

Additive manufacturing marketplaces

-

Tokenized logistics

-

Carbon credit and sustainability tracking

With 3D Printing Ventures funding the technologies — and $3DP providing the transactional backbone — investors gain direct access to the infrastructure of the next industrial revolution.

🚀 Conclusion: Building the Future of Open Industry

Blockchain is redefining how humanity creates — shifting manufacturing from closed hierarchies to open collaboration networks.

Every design, every material, every machine can now connect through shared trust, transparent data, and tokenized incentives.

Through 3D Printing Ventures and 3D Printing Coin ($3DP), this future isn’t theoretical — it’s being built, printed, and tokenized today.

“The blockchain doesn’t just record history — it manufactures the future.”

— 3D Printing Ventures Manifesto

Leave a Reply