How 3D Printing Is Redefining Manufacturing

The Convergence of Additive Manufacturing, AI, Blockchain, Robotics, and Quantum Technology

🔭 The Dawn of a New Industrial Age

For more than a century, manufacturing has followed a familiar rhythm: centralized factories, linear supply chains, and mass production at scale. But a quiet revolution is unfolding — one layer at a time. 3D printing, also known as additive manufacturing (AM), is dismantling the old model and replacing it with something far more agile, intelligent, and decentralized.

At 3D Printing Ventures, we believe this transformation is not happening in isolation. The convergence of AI, blockchain, robotics, and quantum computing with additive manufacturing is redefining not just how products are made — but how innovation, ownership, and value creation itself function in the global economy.

🧩 The Core Disruption: Additive Manufacturing Explained

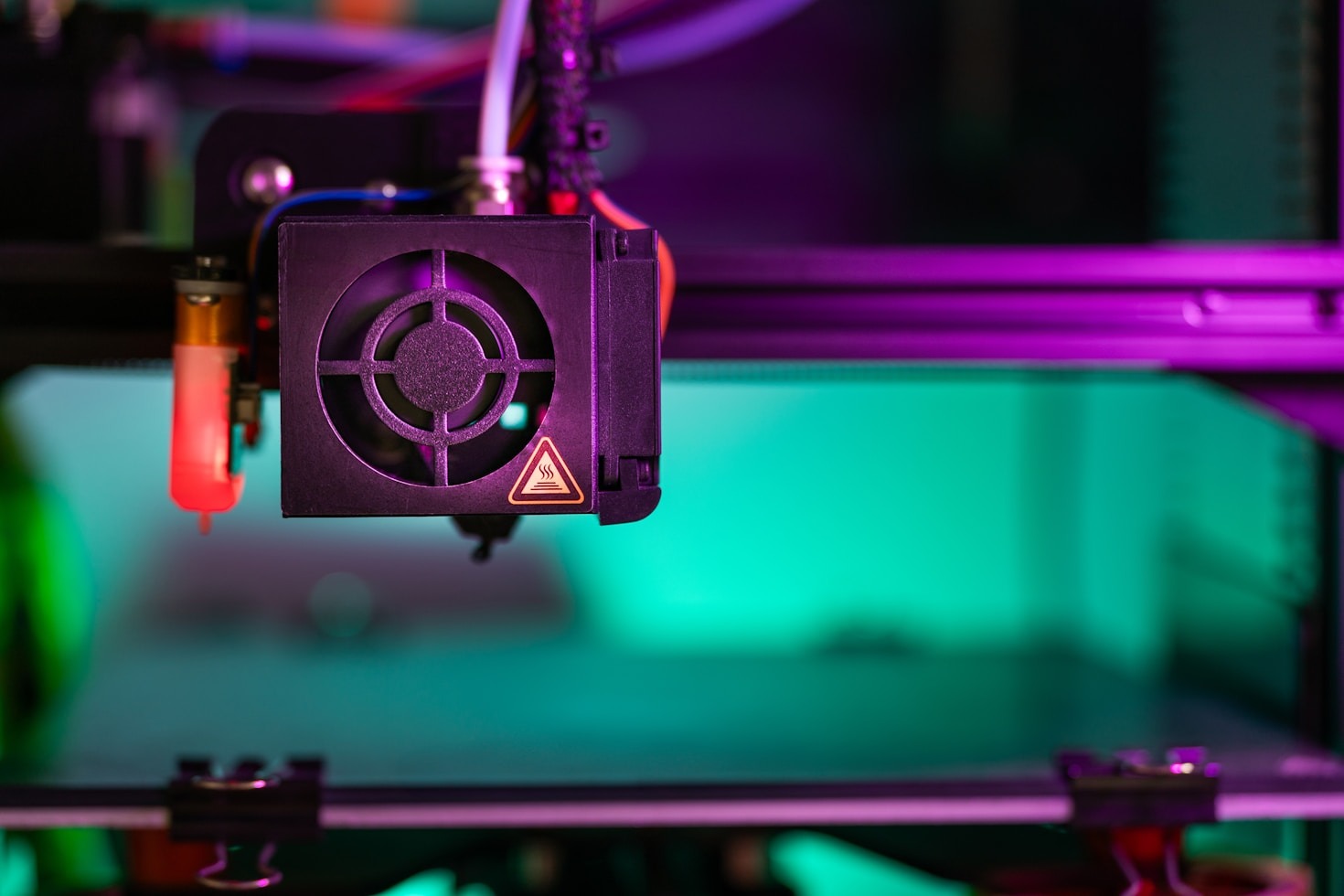

Traditional manufacturing subtracts: it cuts, mills, and molds material into shape.

Additive manufacturing adds — building up materials layer by layer directly from a digital design file. This simple inversion upends the economics of production:

-

Complexity is free. Designs that once required dozens of parts can be printed as one integrated structure.

-

Customization is standard. Every print can be unique without slowing the process.

-

Production is local. Parts can be printed on-demand, near the point of need, reducing inventory and logistics costs.

-

Design is democratized. Anyone with a CAD model and access to a printer becomes a manufacturer.

From aerospace turbine blades to prosthetic limbs, additive manufacturing is enabling a world where digital designs become physical reality — instantly and efficiently.

But what’s emerging now is far more powerful: the fusion of 3D printing with digital intelligence and decentralized infrastructure.

🤖 AI + 3D Printing: The Intelligent Design Factory

Artificial intelligence is unlocking the creative and operational potential of additive manufacturing.

1. Generative Design

AI-driven generative design tools can create thousands of design permutations optimized for strength, weight, and performance — many of which no human would have conceived. Engineers specify the problem; AI evolves the solution.

“AI doesn’t just make better parts — it redefines what’s possible,” says 3D Printing Ventures founder Rich Benvin. “It transforms design into discovery.”

2. Process Automation

Machine learning models monitor sensors during a print, detecting defects in real time and dynamically adjusting printer parameters. The result is self-optimizing manufacturing — machines that learn from every build.

3. Predictive Maintenance

AI systems can forecast printer downtime, analyze toolpath data, and extend machine life through adaptive maintenance schedules.

Over time, entire production cells become autonomous ecosystems — designing, printing, and verifying without human intervention.

🔗 Blockchain + 3D Printing: The Internet of Trust

If AI brings intelligence to 3D printing, blockchain brings integrity.

Every digital design — from a custom implant to an aerospace component — carries immense intellectual and regulatory value. Blockchain ensures these digital blueprints remain secure, traceable, and verifiable throughout their lifecycle.

Key Use Cases:

-

Design NFTs & Licensing: CAD files are tokenized, allowing creators to license designs securely and receive royalties per verified print.

-

Provenance & Compliance: Each print’s material, printer ID, and process data are logged on a distributed ledger — creating an immutable part passport.

-

Tokenized Manufacturing: Smart contracts automate transactions between designers, manufacturers, and customers, enabling decentralized production marketplaces.

-

DAO-Driven Fabrication Networks: Entire production networks governed by community-owned protocols — a vision 3D Printing Ventures calls the “Tokenized Factory.”

In essence, blockchain transforms additive manufacturing from a technical breakthrough into an economic revolution.

⚙️ Robotics + 3D Printing: The Rise of Autonomous Fabrication

Where 3D printing meets robotics, we see the birth of the self-building factory.

Multi-axis robotic arms are now being equipped with extruders, lasers, and toolheads to print at architectural and industrial scales. Robots can:

-

Print large or complex structures impossible for static machines

-

Handle post-processing, machining, and inspection autonomously

-

Coordinate via AI agents and blockchain contracts to allocate work and share resources

These hybrid robotic-additive systems blur the boundary between software, machinery, and supply chain — giving rise to micro-factories that can be deployed anywhere.

“Imagine a network of robotic printers operating like cloud servers,” explains Benvin. “They accept jobs, print parts, self-verify, and get paid — all autonomously.”

This is manufacturing-as-a-service, powered by algorithms, verified by blockchain, and executed by machines.

⚛️ Quantum Computing + 3D Printing: Accelerating the Impossible

Quantum computing might still be in its infancy, but its implications for manufacturing are profound.

Quantum algorithms excel at solving complex optimization problems — precisely the kind that plague design, logistics, and material science.

Within the next decade, quantum-enhanced additive manufacturing could enable:

-

Quantum Material Discovery: Simulating atomic-level interactions to design novel alloys, ceramics, and composites.

-

Optimization Beyond Classical Limits: Reducing support structures, energy use, and print time via quantum-inspired pathfinding.

-

Post-Quantum Security: Ensuring blockchain-based manufacturing networks remain secure as quantum computers become mainstream.

This technology stack — AI + Quantum + Additive — forms the computational backbone of Industry 5.0.

🧠 The Bigger Picture: From Factories to Fabrication Webs

The convergence of these technologies turns centralized production into a distributed, intelligent web of fabrication nodes — what 3D Printing Ventures calls the “Production Internet.”

In this system:

-

Designs are data. AI creates, tests, and iterates digitally.

-

Machines are autonomous. Robotics and additive systems print, assemble, and verify automatically.

-

Ownership is transparent. Blockchain tracks rights, royalties, and compliance.

-

Optimization is quantum. Physics-level modeling feeds smarter material and design choices.

Production becomes decentralized, on-demand, and self-healing.

This is not the next step of manufacturing — it’s a complete reimagining of it.

🌱 Sustainability and Circularity

Additive manufacturing is also the bridge between industrial efficiency and environmental responsibility:

-

Drastically less waste material compared to subtractive methods

-

Lightweight parts that reduce transport emissions

-

Local, on-demand printing minimizing global shipping

-

Recyclable feedstocks and closed-loop materials

When integrated with blockchain-based carbon tracking and AI waste optimization, sustainability becomes measurable and enforceable — not just aspirational.

💡 Investment Outlook: The Smart Money Flows to Convergence

For investors and innovators, convergence represents the next trillion-dollar opportunity.

At 3D Printing Ventures, we track startups and research teams working at these intersections:

-

AI-driven additive design software

-

Blockchain-secured design marketplaces

-

Autonomous robotic micro-factories

-

Quantum-powered materials R&D

-

Tokenized manufacturing networks

Each of these verticals is disruptive alone; together, they redefine manufacturing, logistics, and even global trade.

“The next industrial revolution won’t be built in one factory,” says Benvin. “It will emerge from thousands of connected, intelligent, autonomous fabrication nodes — powered by AI, secured by blockchain, and scaled by robotics.”

🧭 The 3D Printing Ventures Vision

3D Printing Ventures exists to fund, connect, and accelerate the pioneers building this future.

We see 3D printing not as a single technology, but as the foundational layer of a larger convergence stack — one that merges digital intelligence with physical creation.

Our mission is simple:

Empower innovators who merge computation, automation, and fabrication to redefine what’s possible.

📈 The Future of Making

Manufacturing is no longer just about production — it’s about intelligence, decentralization, and adaptability.

3D printing is the gateway technology unlocking that evolution, transforming how we design, build, and distribute everything from spacecraft to sneakers.

As the physical world becomes programmable, one truth stands out:

The future of manufacturing isn’t made — it’s printed.

Leave a Reply